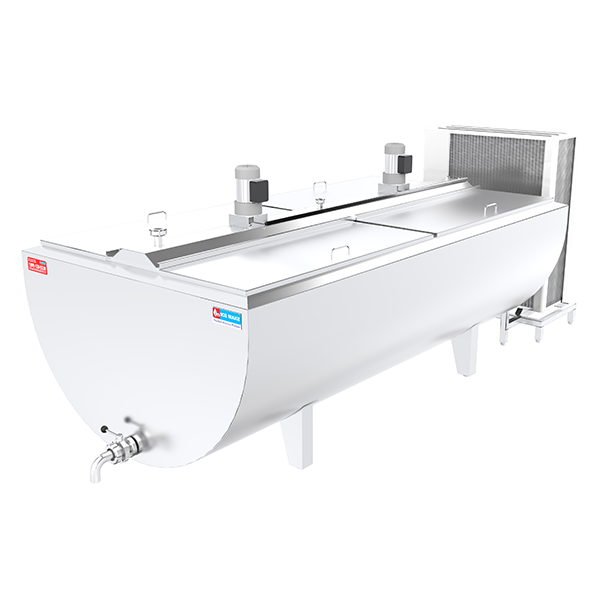

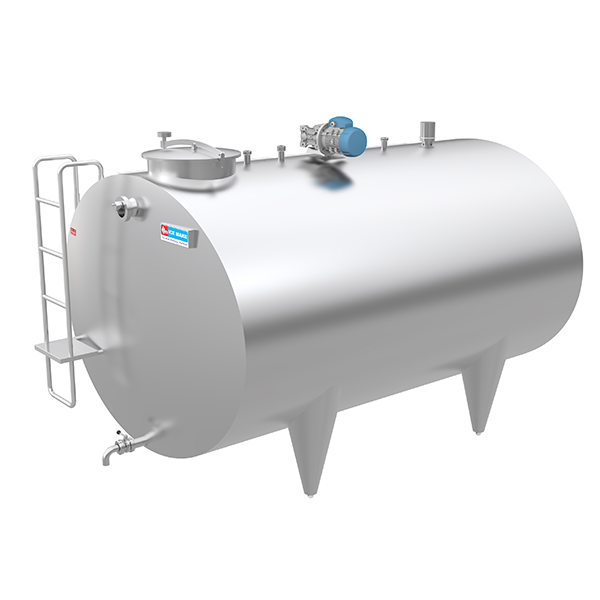

ICE MAKE is a leading manufacturer of Industrial and commercial refrigeration equipment. Since 1993, ICE MAKE is providing expert cooling solutions for dairy industry. We offers vast range of Bulk Milk Chiller and Milk Cans Cooler which is used to cool milk at 4°C and to maintain freshness of milk. Bulk Milk Chiller is the solution for bacteria free milk storage for Dairy/Milk Collection Centers.

Bulk milk chiller range: 250 Litres to 10,000 litres.

Milk cans cooler range: 4 to 18 can storage (can of 30/40 litres).